asco solenoid valve pdf

ASCO Solenoid Valve Overview

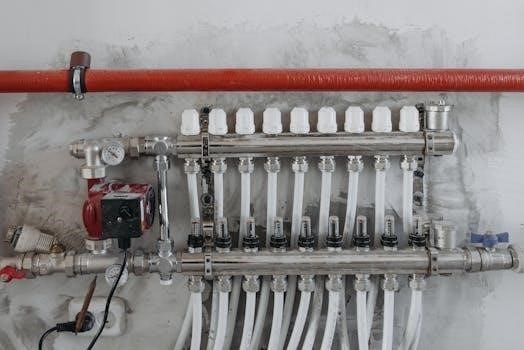

Emerson’s ASCO solenoid valves are known for their industry-standard reliability‚ adaptability‚ and energy efficiency across diverse applications. They feature a solenoid directly mounted on the valve body‚ with a sealed core tube for a compact‚ leaktight assembly. ASCO products are designed for controlling air‚ gas‚ water‚ oil and steam.

ASCO Valve Reliability and Adaptability

ASCO solenoid valves are renowned for their robust construction and consistent performance‚ ensuring reliable operation in demanding industrial environments. Their adaptability is evident in the wide range of pressure ratings‚ sizes‚ and resilient materials available‚ providing solutions for diverse fluid control needs. These valves are designed to minimize internal leakage‚ contributing to efficient system operation and reduced energy consumption. The flexible mounting options further enhance their adaptability‚ allowing for easy integration into various system configurations. ASCO’s commitment to quality and innovation ensures that their solenoid valves maintain high levels of performance across a broad spectrum of applications. Furthermore‚ the ability to quickly disassemble the core tube simplifies maintenance and prolongs the valve’s service life‚ reinforcing its reliability and adaptability.

ASCO 8210 Series Features

The ASCO 8210 series stands out as a popular choice within the RedHat line‚ offering exceptional on-off control through an internal pilot-operated design. These 2-way valves are available in both normally closed and normally open configurations‚ accommodating a wide range of operational needs. With pipe sizes ranging from 3/8 to 2 1/2 inches‚ they are suitable for various industrial applications. The series excels in controlling commercial and industrial gas burners and performs exceptionally well in high-pressure environments. Constructed from either brass or stainless steel‚ the 8210 series offers material flexibility to suit different fluid compatibilities. Furthermore‚ they can be mounted in any position‚ providing added convenience and ease of installation. The ASCO 8210 series is characterized by its robust build and reliable performance‚ making it a trusted solution for many demanding applications.

ASCO Valve Types and Applications

ASCO offers a diverse range of valves‚ including scientific‚ Posiflow proportional‚ and steam/hot water models. These valves are designed for various applications‚ from precise control of liquids and gases to high-temperature steam management.

ASCO Scientific Valves

ASCO scientific valves are micro-miniature‚ general-service valves engineered to precisely manage the flow of liquids and gases. These valves are available at The Valve Shop‚ where a wide selection can be found at discounted prices. Their design is focused on delivering accurate and reliable control‚ which is critical for laboratory and analytical applications. ASCO scientific valves are a crucial component in systems where precise fluid regulation is necessary. They are constructed to handle various media with excellent performance. These valves are ideal for integration into complex systems. ASCO’s scientific valve lineup ensures both reliability and efficiency for a range of fluid control needs. The precision of these valves is crucial in research and industrial settings‚ where even the smallest variations in flow can be significant; These micro-miniature options are a testament to ASCO’s commitment to innovation and quality in fluid control solutions.

ASCO Posiflow Proportional Valves

ASCO Posiflow proportional solenoid valves are designed as 2-way direct-acting or pilot-operated‚ fail-closed proportional control valves. The flow rate through these valves is directly proportional to the electrical input‚ allowing for precise control of fluid flow. These valves are found at The Valve Shop‚ among other places‚ with a wide range of options available. Posiflow valves are suited for applications needing variable flow control‚ such as those in analytical instruments and industrial automation. Their ability to adjust flow rate based on electrical signals makes them versatile in applications requiring dynamic control. The direct-acting and pilot-operated configurations offer flexibility. They provide reliable performance for a range of flow and pressure requirements. ASCO Posiflow valves allow for streamlined systems that meet specific flow demands‚ enhancing operational efficiency and control in various industrial processes.

ASCO Steam-Hot Water Valves

ASCO steam and hot water valves are designed to handle high-temperature fluids‚ offering reliable performance in demanding applications; These valves are available at The Valve Shop‚ among other retailers‚ with a large selection in stock. These valves are used in processes involving steam or hot water‚ such as industrial heating and sterilization systems. An example is a 2/2-way integral pilot-operated solenoid valve handling water up to 50 degrees Celsius‚ with a flow rate of 3.4 cubic meters per hour. These valves often feature robust construction and materials to withstand the harsh conditions of steam and hot water service. They are often integral pilot-operated‚ which helps in achieving reliable sealing and operation. ASCO’s steam and hot water valves ensure precise control of fluid flow‚ contributing to efficient and safe operation of high-temperature systems.

Technical Specifications

ASCO valves feature a wide range of pressure ratings and sizes‚ using resilient materials for long service life. They also have a range of flow and pressure ratings‚ with easy disassembly for maintenance of internal parts.

ASCO Valve Material and Construction

ASCO valves are constructed with a focus on durability and performance‚ utilizing materials suitable for various applications. The valve body is available in brass or stainless steel‚ providing options for different fluid compatibility and environmental conditions. A key feature of ASCO valves is the direct mounting of the solenoid on the valve body‚ creating a compact and leaktight assembly. The core of the solenoid is enclosed in a sealed tube‚ which further contributes to the valve’s leak-proof design. These valves also include a PTFE main disc and UItem piston‚ enhancing sealing and performance. The internal components are designed for easy disassembly‚ allowing for quick maintenance and part replacement. ASCO’s focus on material selection and construction ensures a long service life and low internal leakage‚ making them reliable for diverse fluid control applications. The robust construction enables these valves to withstand a wide range of pressure ratings and operating conditions‚ making them a trusted choice for industrial and commercial settings.

ASCO Valve Electrical Specifications

ASCO solenoid valves come with specific electrical specifications tailored to various power requirements and applications. The electrical components of the valve are designed for both AC and DC operation‚ providing flexibility in installation. The RedHat II/RedHat AC series operates within a nominal ambient temperature range of 32°F to 125°F (0°C to 52°C)‚ while the RedHat II DC series is rated for 32°F to 104°F (0°C to 40°C). For 50 Hz service‚ a 6.1/F solenoid has a watt rating of 8.1 watts. The electrical connections are designed for secure and reliable operation‚ ensuring consistent performance. ASCO provides a variety of coil options to suit different voltage and frequency needs. The solenoid‚ being directly mounted to the valve body‚ allows for a compact design and efficient power transfer‚ contributing to the valve’s overall performance and reliability. These specifications are crucial in ensuring that the valves operate correctly within a given electrical environment.

ASCO Valve Certifications and Safety

ASCO valves are certified according to IEC 61508 and have SIL-3 capability with TÜV and Exida certifications. They meet applicable CE directives‚ are CSA certified‚ and UL listed‚ ensuring compliance with various industry standards for safety and performance.

ASCO Valve SIL-3 Capability

ASCO valves are engineered with a strong emphasis on functional safety‚ achieving a SIL-3 rating as per IEC 61508. This certification signifies that these valves are suitable for use in safety-critical applications where a high level of risk reduction is required. The SIL-3 capability of ASCO solenoid valves is verified by third-party organizations such as TÜV and Exida‚ ensuring that they meet stringent safety requirements. This level of safety integrity is crucial in industries such as chemical processing‚ oil and gas‚ and power generation‚ where valve failure can have significant consequences. The valves are designed to minimize the probability of dangerous failure‚ contributing to overall system reliability and protection. The robust design and manufacturing processes of ASCO valves ensure their consistent performance in demanding environments‚ giving users confidence in their safety-related functions and compliance with recognized safety standards. This dedication to safety is a key reason why ASCO valves are a trusted choice for critical applications across various sectors‚ guaranteeing both operational and environmental security.

ASCO Valve Industry Standards Compliance

ASCO valves are designed and manufactured to comply with a wide range of industry standards‚ ensuring their suitability for various applications globally. They meet applicable CE directives‚ indicating conformity with European health‚ safety‚ and environmental protection standards. Many ASCO valves are also UL listed‚ signifying their safety when used in accordance with specific guidelines. Furthermore‚ ASCO valves are CSA certified‚ confirming their compliance with Canadian safety standards; These certifications demonstrate ASCO’s commitment to producing high-quality valves that adhere to international regulatory requirements‚ providing users with confidence in their performance and safety. The valves are built to meet strict industry specifications‚ ensuring they integrate seamlessly into various systems and processes. Additionally‚ ASCO valves are often certified to meet specific industry requirements‚ such as those for use in hazardous locations or specific fluid control applications. This commitment to meeting industry standards ensures that ASCO valves are a dependable choice for diverse sectors‚ providing compliance and reliability.